HXMD

V210RC

CHINA

HRC48-52

FORGING

YES

GREY/BLACK

5-7days can deliver if in stock

| Availability: | |

|---|---|

The V210RC Forged Mini Excavator Bucket Teeth are precision-engineered to enhance the performance and durability of mini excavators in various applications. These forged bucket teeth offer superior strength and wear resistance, making them ideal for demanding construction and excavation tasks.

Manufactured using advanced forging technology, the V210RC bucket teeth are made from high-quality steel. The forging process improves the internal structure, making these teeth more durable and wear-resistant. With a hardness rating of HRC48-52, they are built to withstand tough working conditions, ensuring longer operational life and reduced downtime.

These excavator teeth types are specifically designed for mini excavators, providing an efficient digging solution for smaller projects. Whether you're working on landscaping, trenching, or demolition, the V210RC bucket teeth deliver reliable and precise performance. Their robust design ensures that your mini excavator can handle tough terrains with ease.

The V210RC forged mini excavator bucket teeth are available with customizable options, allowing for a perfect fit for your equipment. They are a cost-effective solution for minimizing frequent replacements and downtime. These teeth ensure high productivity while maintaining low maintenance costs, making them a valuable addition to your machinery.

Construction: Ideal for small construction projects that require precision digging and reliability.

Landscaping: Perfect for digging tasks in landscaping, offering efficient soil penetration.

Demolition: Effective for handling demolition debris, ensuring smooth and powerful operation.

Material: High-strength forged steel for durability.

Design: Tailored for mini excavators, ensuring a perfect fit.

Hardness: HRC48-52 for enhanced wear resistance.

Customizable: Available to meet specific equipment requirements.

Efficiency: Designed to reduce downtime and increase operational productivity.

Cost-Effective: Long-lasting performance to minimize frequent replacements.

Excavator bucket teeth are essential components of excavators.

They consist of a combination of tooth bases and tooth tips, which are connected by pins.

Ensure that the bucket is fully protected, preventing easy damage.

Enhance the flexibility of the excavator during operation.

Provide a buffering function to assist with excavation tasks.

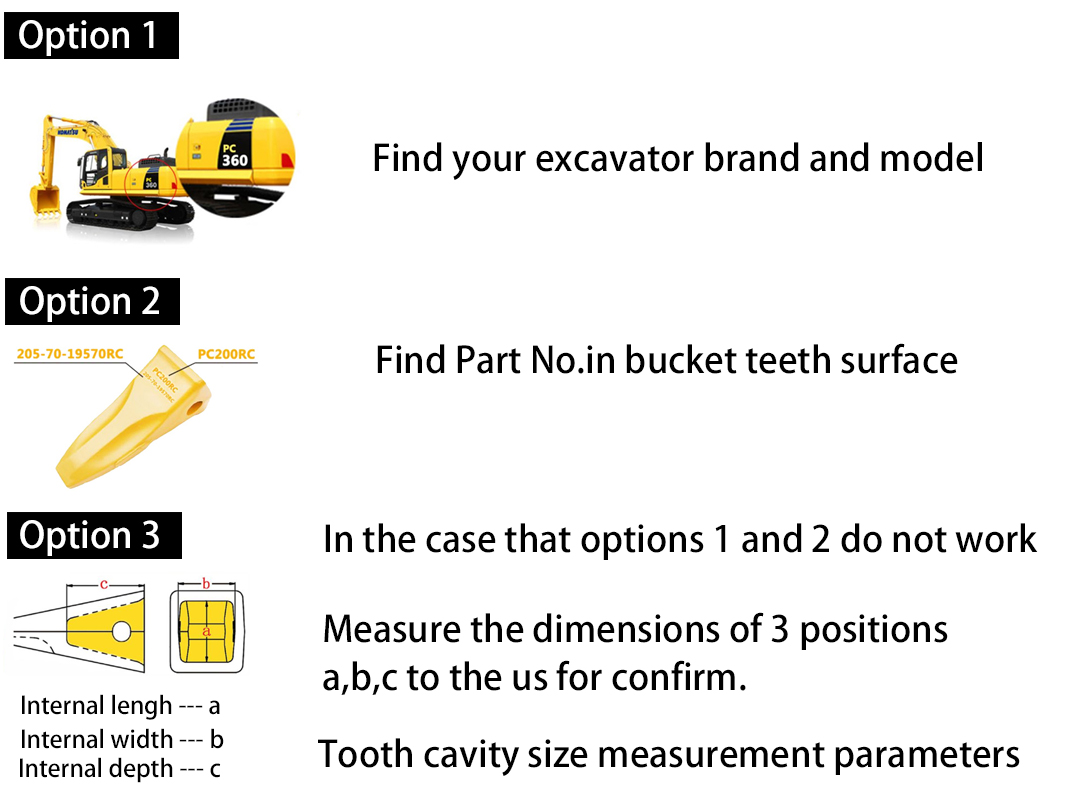

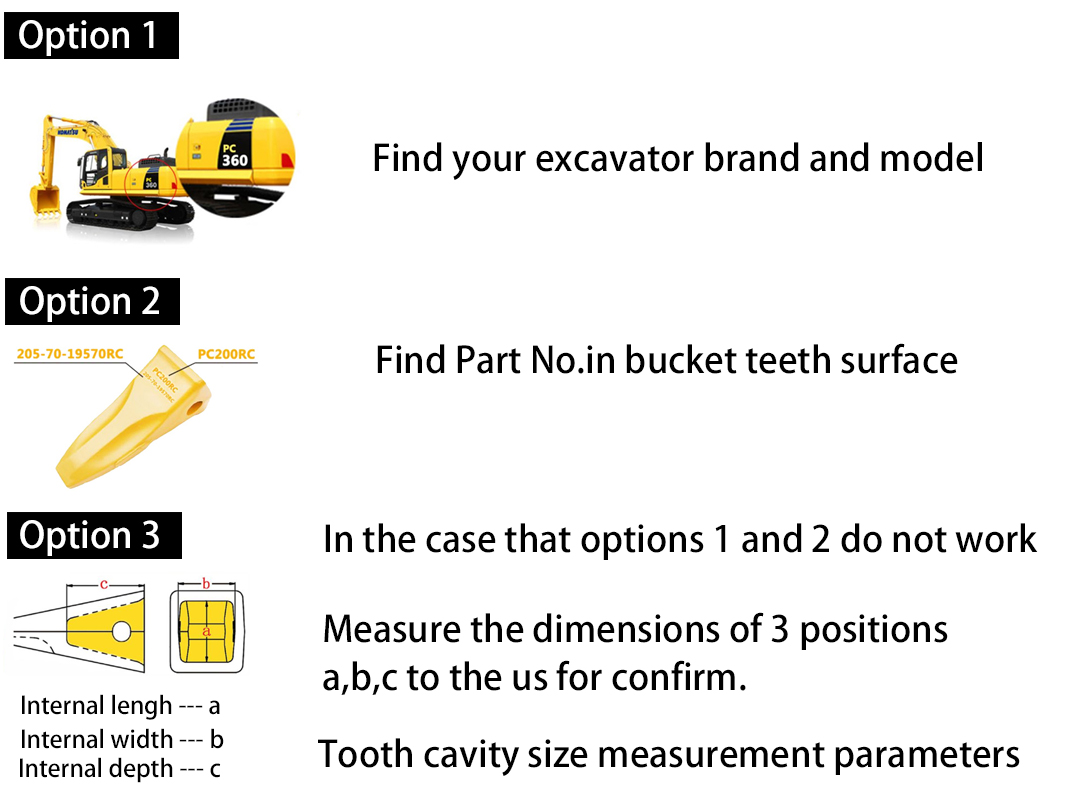

Follow the steps below to select and install the right bucket teeth for your excavator.

Option 1:

Identify your excavator brand and model to ensure compatibility with the bucket teeth.

Option 2:

Locate the part number on the surface of the bucket teeth for accurate matching.

Option 3:

If options 1 and 2 do not work, measure the dimensions of three positions:

Internal length (a)

Internal width (b)

Internal depth (c)

Then, provide these measurements to us for confirmation.

This method ensures you choose the correct excavator bucket teeth for your equipment.

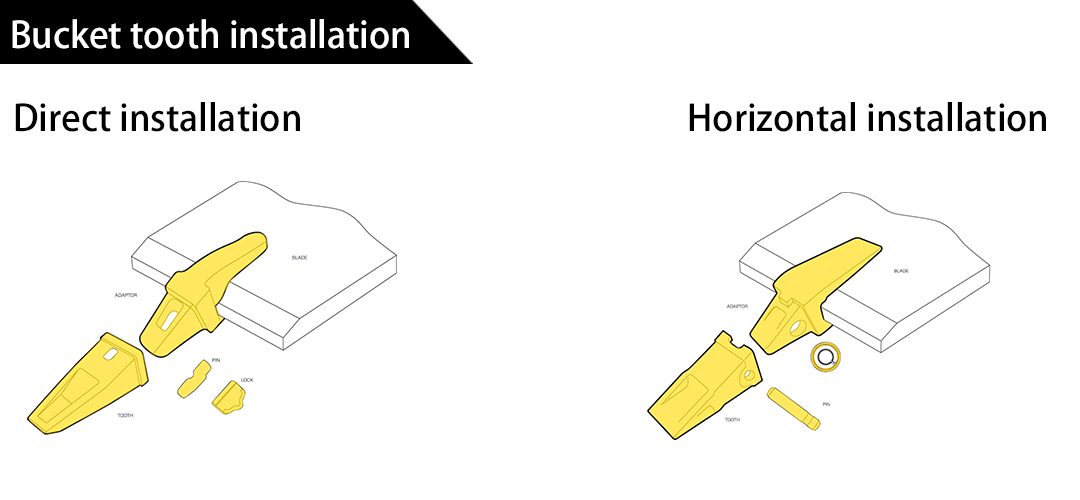

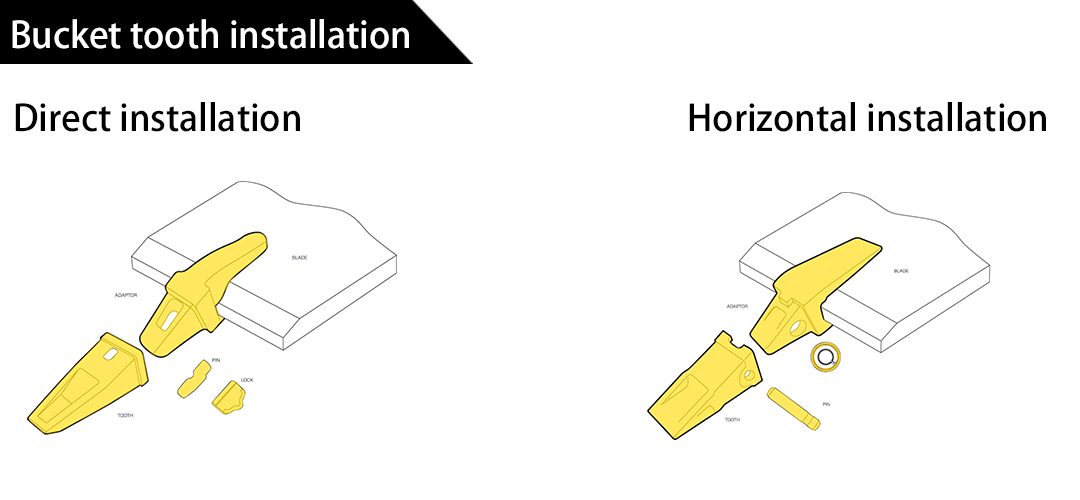

This refers to installing the bucket tooth pin vertically, with the pin positioned perpendicular to the front of the excavator bucket tooth.

This refers to installing the bucket tooth pin parallel to the front of the excavator bucket tooth.

The V210RC Forged Mini Excavator Bucket Teeth are precision-engineered to enhance the performance and durability of mini excavators in various applications. These forged bucket teeth offer superior strength and wear resistance, making them ideal for demanding construction and excavation tasks.

Manufactured using advanced forging technology, the V210RC bucket teeth are made from high-quality steel. The forging process improves the internal structure, making these teeth more durable and wear-resistant. With a hardness rating of HRC48-52, they are built to withstand tough working conditions, ensuring longer operational life and reduced downtime.

These excavator teeth types are specifically designed for mini excavators, providing an efficient digging solution for smaller projects. Whether you're working on landscaping, trenching, or demolition, the V210RC bucket teeth deliver reliable and precise performance. Their robust design ensures that your mini excavator can handle tough terrains with ease.

The V210RC forged mini excavator bucket teeth are available with customizable options, allowing for a perfect fit for your equipment. They are a cost-effective solution for minimizing frequent replacements and downtime. These teeth ensure high productivity while maintaining low maintenance costs, making them a valuable addition to your machinery.

Construction: Ideal for small construction projects that require precision digging and reliability.

Landscaping: Perfect for digging tasks in landscaping, offering efficient soil penetration.

Demolition: Effective for handling demolition debris, ensuring smooth and powerful operation.

Material: High-strength forged steel for durability.

Design: Tailored for mini excavators, ensuring a perfect fit.

Hardness: HRC48-52 for enhanced wear resistance.

Customizable: Available to meet specific equipment requirements.

Efficiency: Designed to reduce downtime and increase operational productivity.

Cost-Effective: Long-lasting performance to minimize frequent replacements.

Excavator bucket teeth are essential components of excavators.

They consist of a combination of tooth bases and tooth tips, which are connected by pins.

Ensure that the bucket is fully protected, preventing easy damage.

Enhance the flexibility of the excavator during operation.

Provide a buffering function to assist with excavation tasks.

Follow the steps below to select and install the right bucket teeth for your excavator.

Option 1:

Identify your excavator brand and model to ensure compatibility with the bucket teeth.

Option 2:

Locate the part number on the surface of the bucket teeth for accurate matching.

Option 3:

If options 1 and 2 do not work, measure the dimensions of three positions:

Internal length (a)

Internal width (b)

Internal depth (c)

Then, provide these measurements to us for confirmation.

This method ensures you choose the correct excavator bucket teeth for your equipment.

This refers to installing the bucket tooth pin vertically, with the pin positioned perpendicular to the front of the excavator bucket tooth.

This refers to installing the bucket tooth pin parallel to the front of the excavator bucket tooth.

At HXMD, we specialize in forging high-quality V210RC Forged Mini Excavator Bucket Teeth and offer extensive expertise in a wide range of excavator spare parts. Our offerings include bucket teeth, pins & bushings, H-link, I-link, track rollers, idlers, sprockets, carrier rollers, track links, track shoes, blades, and more.

We are committed to providing professional assistance with most bucket accessories, ensuring your excavator operates efficiently. Additionally, we offer a convenient one-stop shopping service to meet all your spare part needs.

Industry and Trade Integration:

Our company combines industry and trade, offering high-quality products like the V210RC Forged Mini Excavator Bucket Teeth at prices close to the cost price.

Forged Excellence:

All our products are forged, with forged bucket teeth like the V210RC offering superior structure, high mechanical properties, enhanced wear resistance, and longer service life.

Complete Production System:

With a fully integrated production process and experienced workers, we ensure high-quality standards throughout manufacturing.

Global Reputation:

More than half of our products, including the V210RC Forged Mini Excavator Bucket Teeth, are exported globally, receiving excellent feedback and building strong reputations.

24/7 Professional Sales Team:

Our dedicated sales team is available around the clock, ready to assist with any inquiries or orders.

Efficient After-Sales Service:

Our knowledgeable after-sales staff is quick and professional, ensuring all issues are resolved promptly and efficiently.

At HXMD, we specialize in forging high-quality V210RC Forged Mini Excavator Bucket Teeth and offer extensive expertise in a wide range of excavator spare parts. Our offerings include bucket teeth, pins & bushings, H-link, I-link, track rollers, idlers, sprockets, carrier rollers, track links, track shoes, blades, and more.

We are committed to providing professional assistance with most bucket accessories, ensuring your excavator operates efficiently. Additionally, we offer a convenient one-stop shopping service to meet all your spare part needs.

Industry and Trade Integration:

Our company combines industry and trade, offering high-quality products like the V210RC Forged Mini Excavator Bucket Teeth at prices close to the cost price.

Forged Excellence:

All our products are forged, with forged bucket teeth like the V210RC offering superior structure, high mechanical properties, enhanced wear resistance, and longer service life.

Complete Production System:

With a fully integrated production process and experienced workers, we ensure high-quality standards throughout manufacturing.

Global Reputation:

More than half of our products, including the V210RC Forged Mini Excavator Bucket Teeth, are exported globally, receiving excellent feedback and building strong reputations.

24/7 Professional Sales Team:

Our dedicated sales team is available around the clock, ready to assist with any inquiries or orders.

Efficient After-Sales Service:

Our knowledgeable after-sales staff is quick and professional, ensuring all issues are resolved promptly and efficiently.